(ThyBlackMan.com) In an era where aesthetics and functionality go hand in hand, advanced protective layers have become essential for maintaining sleek and clean surfaces. From consumer electronics to automotive interiors, these layers provide a combination of durability, usability, and enhanced visual appeal. A prime example of this innovation is anti-fingerprint coatings, which have gained significant traction for their ability to resist smudges and maintain a polished look. These protective solutions cater to a wide range of applications, ensuring surfaces remain pristine and easy to maintain.

The Need for Advanced Protective Layers

Modern products often prioritize minimalistic and high-gloss finishes, making them visually appealing but prone to wear and tear. Without adequate protection, surfaces can quickly accumulate scratches, fingerprints, and stains, compromising their appearance and usability. Advanced protective layers address these challenges by offering:

- Resistance to Environmental Factors: Protection from moisture, UV light, and temperature fluctuations.

- Enhanced Durability: Prevention of scratches, abrasions, and other physical damage.

- Ease of Maintenance: Simplified cleaning routines due to anti-smudge and self-cleaning properties.

These features make protective coatings indispensable in industries ranging from consumer electronics to architecture.

Anti-Fingerprint Coatings: A Game-Changer

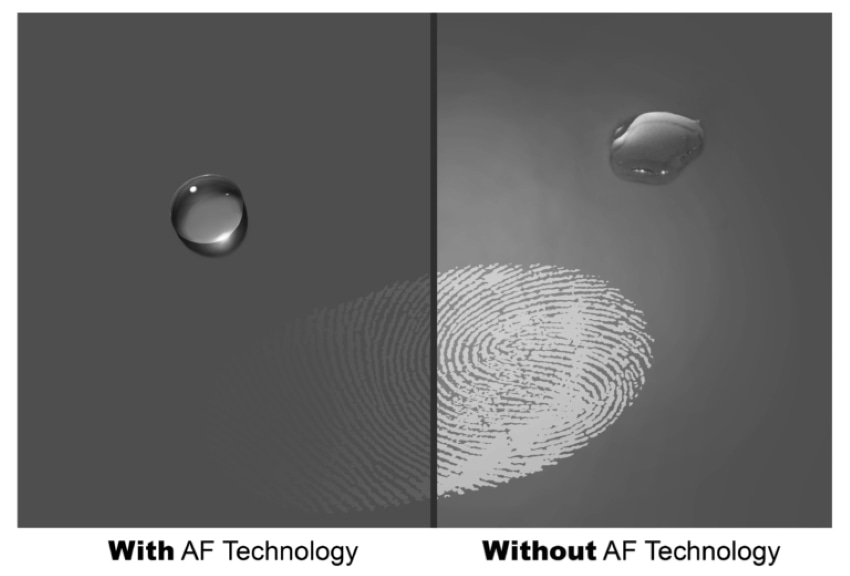

Anti-fingerprint coatings have emerged as a revolutionary solution for maintaining clean, touch-friendly surfaces. These coatings create a thin, transparent layer that repels oils and moisture, preventing fingerprints and smudges from adhering to the surface.

Applications of Anti-Fingerprint Coatings

- Consumer Electronics: Screens and casings of smartphones, tablets, and laptops remain smudge-free, improving user experience and reducing maintenance efforts.

- Kitchen Appliances: Stainless steel surfaces on refrigerators, ovens, and dishwashers stay spotless and require minimal cleaning.

- Automotive Interiors: Touchscreens, dashboard panels, and door handles maintain a sleek and polished look despite frequent contact.

- Architectural Glass: Windows and glass partitions treated with anti-fingerprint coatings are easier to clean, making them ideal for commercial and residential spaces.

These coatings not only enhance the appearance of surfaces but also extend their lifespan by minimizing wear caused by repeated cleaning.

Benefits of Advanced Protective Layers

Protective layers offer numerous advantages, making them an integral part of product design and maintenance strategies.

1. Improved Aesthetics

By maintaining a clean and polished finish, protective layers preserve the visual appeal of surfaces. Whether it’s a glossy smartphone screen or a matte dashboard, the right coating ensures the surface looks flawless.

2. Reduced Maintenance

Smudge-resistant and hydrophobic properties reduce the frequency and effort required for cleaning, saving time and resources for users.

3. Enhanced Durability

Protective layers shield surfaces from scratches, abrasions, and environmental damage, ensuring products remain functional and visually appealing for longer.

4. Hygienic Properties

Many modern coatings include antimicrobial features that inhibit the growth of bacteria and other pathogens, contributing to cleaner and safer environments.

5. Sustainability

By extending the lifespan of products, protective layers reduce waste and promote sustainable consumption.

Innovations in Protective Layer Technology

As industries continue to innovate, protective layer technologies are becoming more advanced, offering new possibilities for functionality and design.

1. Self-Healing Coatings

These coatings use materials that can repair minor scratches and scuffs on their own, making them ideal for automotive finishes and high-touch surfaces.

2. Smart Coatings

Responsive to environmental changes, smart coatings can adjust their properties based on factors like temperature or light exposure. For example, photochromic coatings change color in sunlight, while thermochromic coatings react to heat.

3. Sustainable Coatings

Eco-friendly options, such as biodegradable or low-VOC (volatile organic compound) coatings, align with the growing demand for environmentally responsible products.

4. Nanotechnology Integration

Nano-scale coatings enhance surface properties by creating an almost invisible barrier. These coatings provide superior resistance to dirt, water, and oil, making them indispensable for modern product designs.

Choosing the Right Protective Layer

When selecting a protective layer, it’s essential to consider factors such as:

- Material Compatibility: Ensure the coating is suitable for the surface material (e.g., glass, metal, or plastic).

- Environmental Exposure: Evaluate the surface’s exposure to moisture, UV rays, or temperature fluctuations.

- Aesthetic Preferences: Decide on the desired finish, such as matte, glossy, or textured.

- Functional Requirements: Consider additional features like antimicrobial properties, self-cleaning capabilities, or anti-scratch resistance.

The Future of Surface Protection

The evolution of protective layers is driving advancements in both design and functionality. As technologies like anti-fingerprint coatings and self-healing materials become more accessible, they will play a crucial role in shaping the products and environments of tomorrow. By combining practicality with visual excellence, these innovations promise a future where surfaces remain sleek, clean, and effortlessly maintained across all industries.

Staff Writer; Larry Hall

Leave a Reply