(ThyBlackMan.com) Growing a wine business beyond the boutique stage requires more than great grapes and skilled winemaking. The transition from small-batch production to commercial viability hinges on infrastructure decisions that either enable growth or create expensive bottlenecks. While the romance of winemaking often centers on vineyard management and barrel aging, the operational realities of running a profitable winery demand attention to less glamorous but equally critical investments.

The wineries that successfully scale share a common understanding: production capacity means nothing if you can’t efficiently get your product into bottles and out the door. This fundamental truth shapes every infrastructure decision from equipment purchases to facility layout, and it separates wineries that grow sustainably from those that struggle to meet demand despite producing excellent wine.

The Bottling Operation as Growth Foundation

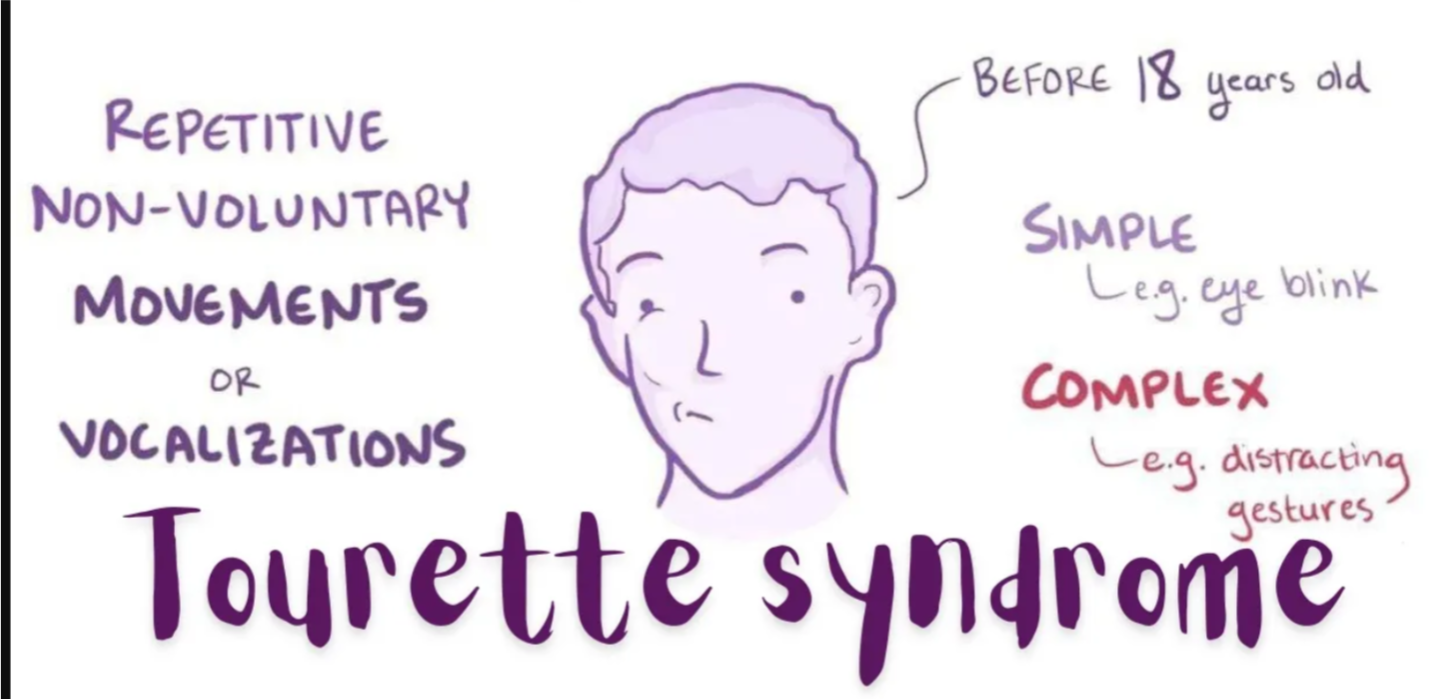

Most wineries hit their first real scaling challenge at the bottling stage. Manual bottling operations work fine for a few hundred cases per year, but they become prohibitively expensive and time-consuming as production increases. The math is straightforward—hand-bottling a thousand cases takes substantially longer than producing the wine itself, creating a situation where finished product sits in tanks while the bottling process becomes the limiting factor for cash flow.

Investing in proper bottling infrastructure addresses multiple business challenges simultaneously. A quality wine bottling machine reduces labor costs per unit, improves fill consistency, minimizes oxygen exposure, and accelerates the time from finished wine to sellable product. These improvements directly impact profitability while creating the capacity needed to pursue wholesale accounts that require regular, reliable shipments.

The difference between semi-automatic and fully automatic systems comes down to production volume and labor availability. Semi-automatic equipment requires operators for certain functions but still delivers significant efficiency gains over manual operations. Fully automatic lines handle everything from bottle rinsing through corking and capsule application, making them worthwhile for wineries producing above certain volume thresholds. The key is matching equipment capabilities to actual production needs rather than buying either too little capacity or overinvesting in automation that runs below optimal efficiency.

Quality Control Systems That Protect Your Brand

Consistency matters in commercial wine sales. Restaurant buyers and distributors need confidence that every bottle meets the same standard, and quality control systems provide that assurance while protecting against costly recalls or reputation damage. The infrastructure for quality management extends beyond laboratory equipment to include sanitation protocols, temperature control systems, and documentation processes that track wine from tank to bottle.

Temperature-controlled storage represents another critical infrastructure investment that pays dividends through product stability and shelf-life extension. Climate control isn’t optional for wineries in warm regions, but even moderate climates benefit from the ability to hold finished goods at optimal temperatures before shipping. This capability prevents refermentation issues, preserves wine characteristics, and provides flexibility in timing sales to match market demand rather than being forced to move product immediately after bottling.

Testing equipment for basic wine analysis—pH meters, titration setups, and sensory evaluation spaces—allows wineries to maintain quality standards without relying entirely on outside laboratories. While comprehensive analysis still requires professional lab services, in-house testing capabilities catch problems early and reduce turnaround time for routine checks during production. This infrastructure investment improves decision-making speed and reduces the risk of processing entire batches before discovering issues.

Storage and Fulfillment Capacity

Warehouse space seems like a simple calculation, but wineries often underestimate their needs during growth phases. Finished goods inventory, empty bottles, packaging materials, and barrel storage all compete for square footage. The wineries that scale smoothly plan for inventory growth before it becomes critical, securing storage capacity that accommodates seasonal fluctuations and allows for advance purchasing of packaging materials when pricing is favorable.

Fulfillment infrastructure includes more than just storage racks. Efficient order processing requires organized systems for inventory management, picking areas designed for quick access to popular SKUs, and shipping stations equipped for the various box sizes and carrier requirements that wine shipping demands. These operational details rarely get attention during the romantic phase of starting a winery, but they determine whether fulfillment costs eat into margins or remain manageable as order volume increases.

The decision between handling fulfillment in-house versus outsourcing to third-party logistics providers depends on volume, complexity, and geographic distribution needs. In-house fulfillment provides control and works well for wineries with regional distribution or strong direct-to-consumer sales within limited shipping zones. Third-party logistics becomes attractive when shipping volumes justify the service costs or when managing multiple state compliance requirements becomes too complex for internal staff to handle efficiently.

Production Planning and Process Flow

Facility layout impacts efficiency more than most winery owners initially recognize. The physical path that wine takes from crush pad through fermentation, aging, bottling, and storage should minimize unnecessary movement and create logical workflow patterns. Retrofitting existing buildings often forces compromises, but even small layout improvements reduce labor costs and processing time while decreasing the risk of product damage during transfers.

Crush equipment capacity needs to match vineyard production with some buffer for vintage variation and purchased fruit. Under-capacity at crush creates rushed operations and quality compromises during the narrow harvest window, while excessive capacity means expensive equipment sitting idle most of the year. Finding the right balance requires honest assessment of growth plans and realistic evaluation of whether custom crush services might provide better economics than owning all processing equipment.

Barrel programs represent significant capital tied up in assets that provide no immediate return. The romance of barrel aging is real, but the business reality requires calculating carrying costs, storage needs, and the extended timeline before those investments turn into revenue. Wineries scaling successfully often develop blended programs that use some barrel aging for premium products while producing other wines with less capital-intensive aging methods, creating cash flow diversity that funds continued growth.

Making Infrastructure Decisions That Support Growth

The most successful scaling decisions start with clear understanding of target markets and realistic volume projections. Equipment that makes sense for a winery producing five thousand cases annually becomes a bottleneck at ten thousand cases, while overbuilding infrastructure for aspirational volumes that may never materialize wastes capital that could fund marketing or vineyard development.

Financial planning for infrastructure requires looking beyond purchase prices to installation costs, ongoing maintenance, training needs, and operational expenses. A bottling line that seems affordable might require electrical upgrades, compressed air systems, and facility modifications that double the total investment. Similarly, equipment that reduces labor costs per bottle only delivers returns if production volume is sufficient to keep it running regularly.

The wineries that build sustainable growth create infrastructure gradually, matching investments to achieved milestones rather than betting everything on projected success. This measured approach reduces financial risk while providing flexibility to adjust plans as market realities become clearer. It also prevents the common trap of having beautiful equipment that exceeds actual production needs, tying up capital without generating proportional returns.

Building a scalable wine business requires balancing passion with pragmatism, investing in infrastructure that enables growth while maintaining the quality standards that created market interest in the first place. The right equipment and systems create operational capacity that turns good wine into a sustainable business, transforming careful winemaking into consistent commercial success.

Staff Writer; Greg Jones

Leave a Reply